John R. Bentley 2013-19.

Fabricating stainless steel

Fittings for the Methanol Tank

for the burner of the model D-type boiler

Jan 2013 - Oct 2019.

John R. Bentley 2013-19.

Fabricating stainless steel

Fittings for the Methanol Tank

for the burner of the model D-type boiler

First: the pressure relief valve

This relief valve is based on a design by Less Kerr that I saw in an article about a small methylated spirit burner in the 26 May-8 June 2006 issue of Model Engineer. Mine is larger due to a more sizable tank and proportions and materials are different, but the concept is the same.

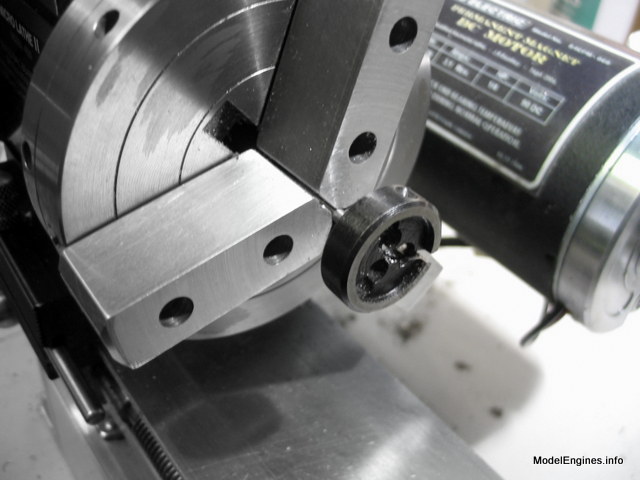

I was off to a great start, carefully cutting the thread on the stainless steel body. I used my Craftex mini lathe with a spindle crank for human power which provides better control and gives a good finish when cutting threads. I paid very close attention since I wanted a good smooth fit into the fuel tank top bush as this opening also serves as the fuel filler. All this fancy talk about precision and finish is just fine but attention to the basics is more important - I cut a left hand thread by mistake!

On the second attempt I got it right :-)

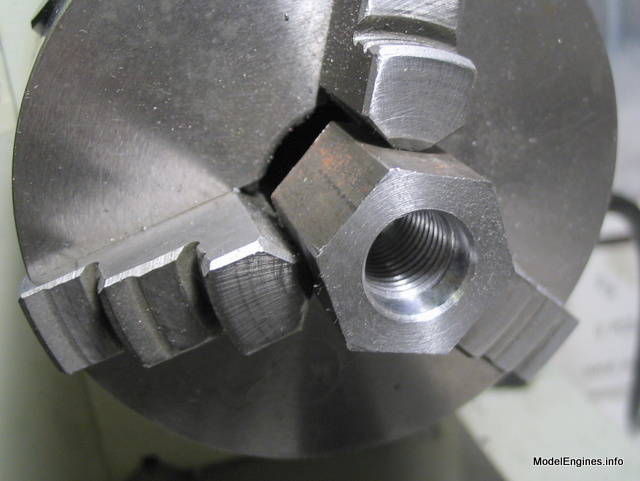

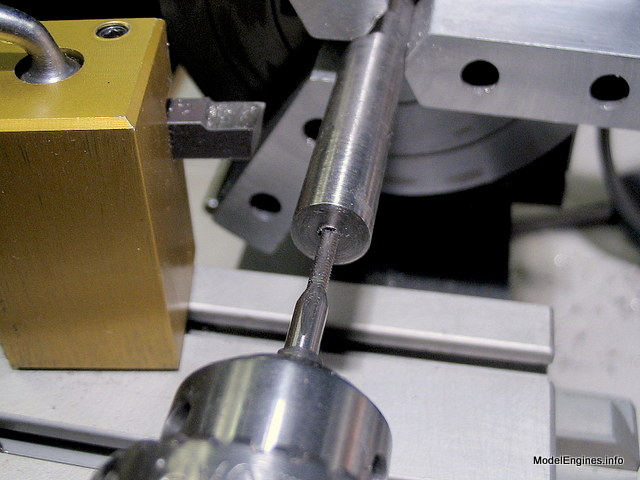

Drilling the body

Making a sturdy threaded mandrel to hold the valve body for knurling

It seems to get an adquate grip

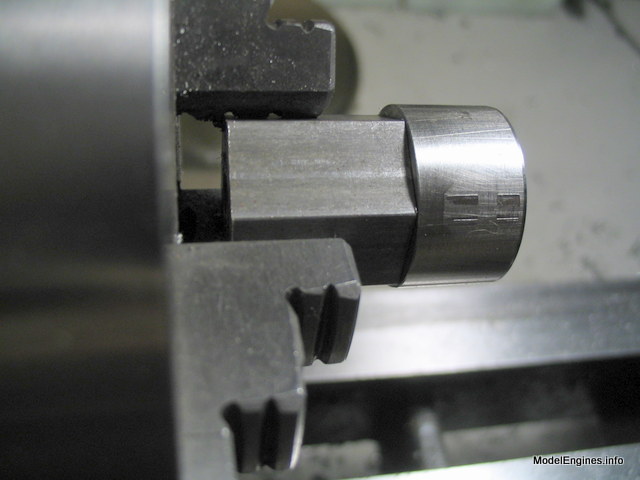

Profiled for the knurling operation with the outer end supported by the tailstock center

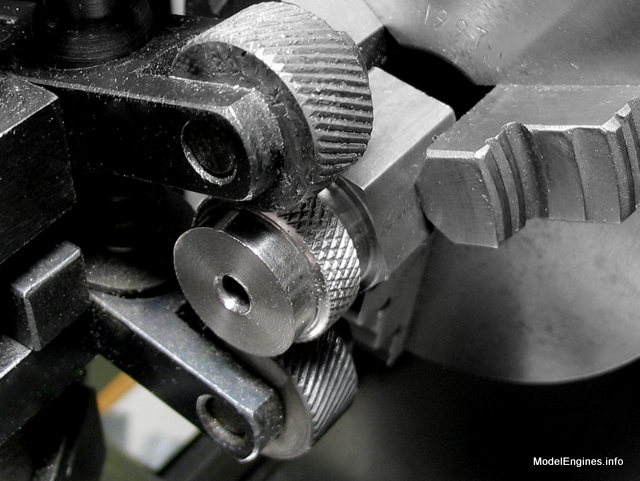

The valve body (center) squeezed between the two knurls in my Craftex mini lathe

Flattening the bottom of the hole with an endmill

The completed body removed from its mandrel

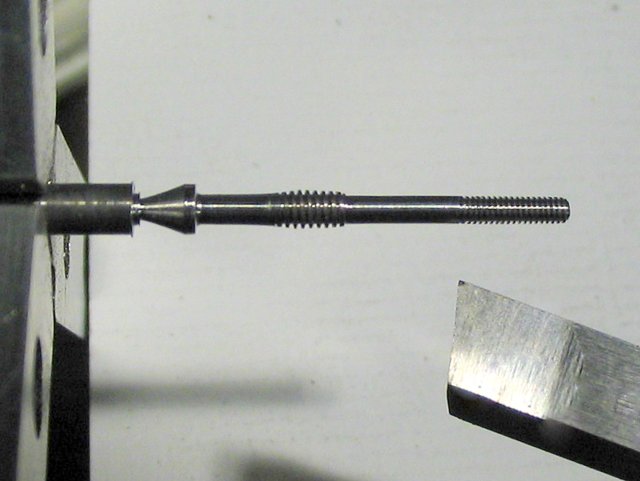

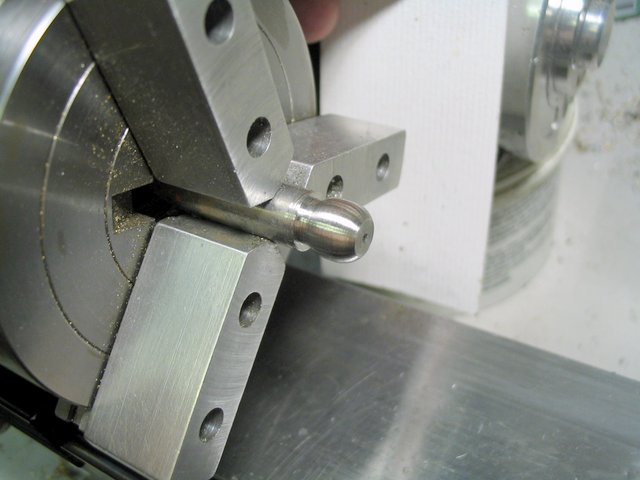

Threading the end of the valve spindle

Making an end retainer for the stainless steel valve spring

The few parts which make up the valve

The following views show the finished relief valve for the methanol fuel tank

Pressure is relieved around the central piece which is the valve spindle

Next: the methanol tank valve

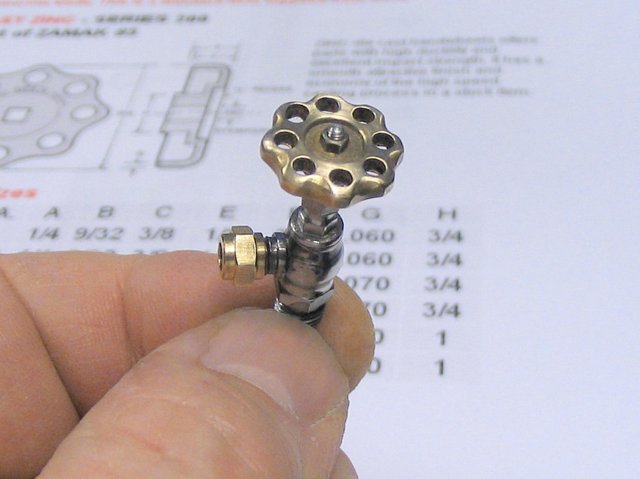

As this will be the fuel regulator and main tank shutoff a large handle is appropriate

This valve is an adaption of a simple screw down needle valve

It is not really very big

The body was turned from stainless steel in a Taig lathe

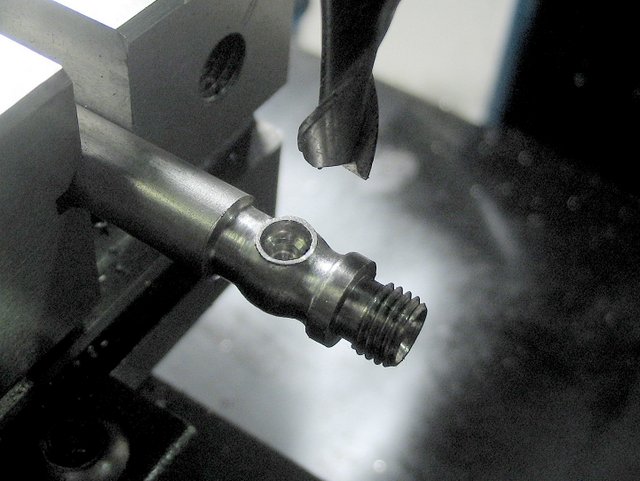

A flat was milled and a hole drilled to mount the spigot

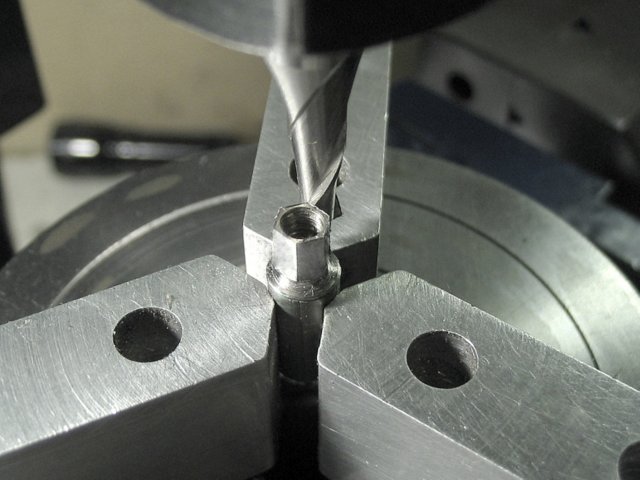

Milling a hex section at the base of the valve body

The completed hex

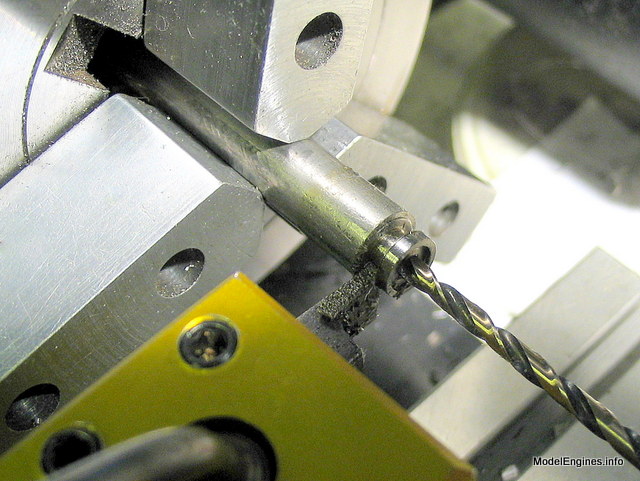

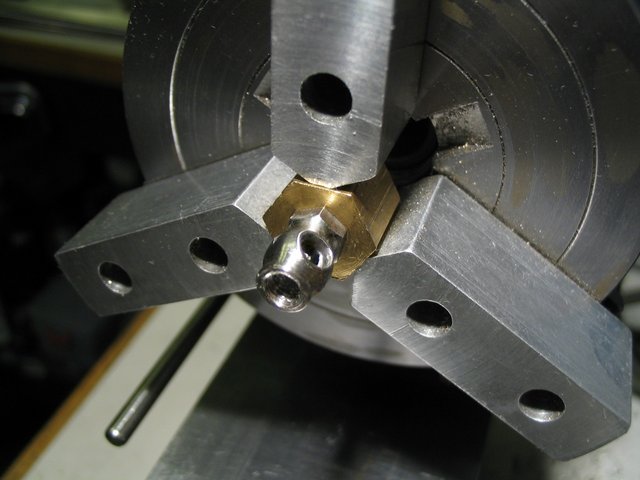

Valve body parted off from stock and held in a brass mandrel for drilling and threading

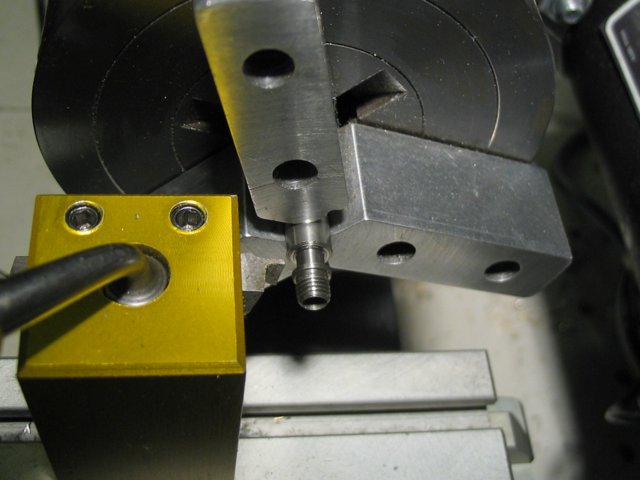

Making the spigot

Spigot and body to be silver brazed together

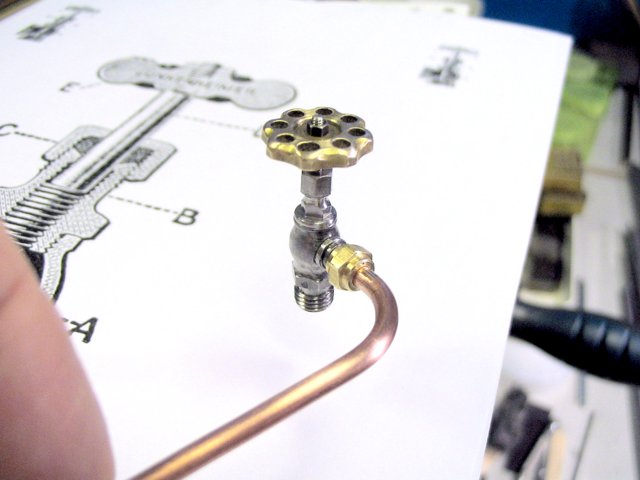

Starting to look like a valve (I hope)

Turning the valve spindle

Making the packing nut for the top

Turning the handle from naval brass

I copied a very common North American handle design

Milling the flutes

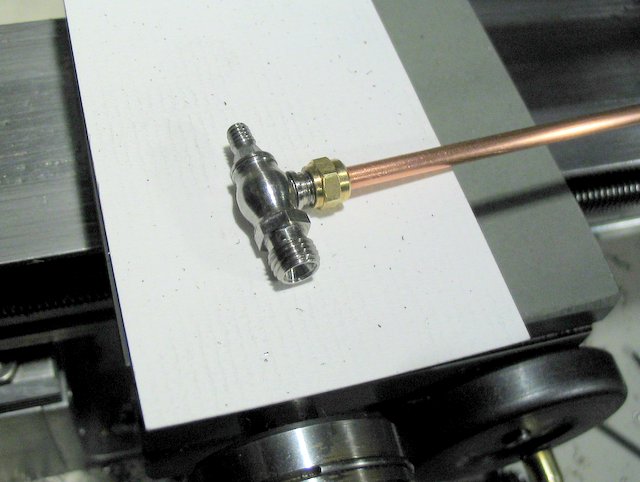

All the valve components (with the spigot already attached to the body)

The completed valve

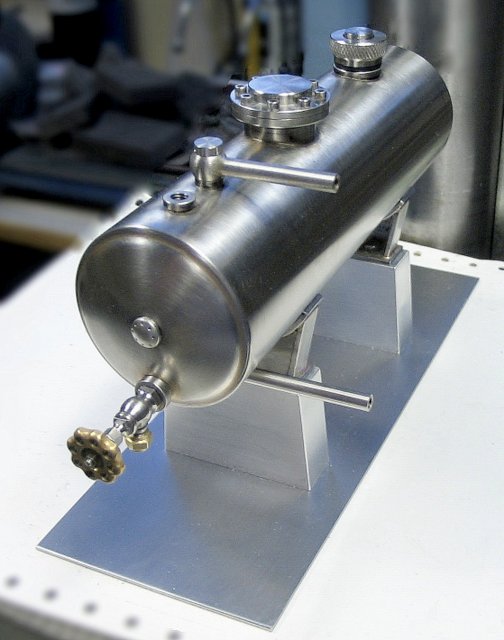

Tank mounting: Saddles and Piers

The saddles are located and held against the shell by bolting into blind threaded bushes in the bottom of the tank

Drilling the positioning holes

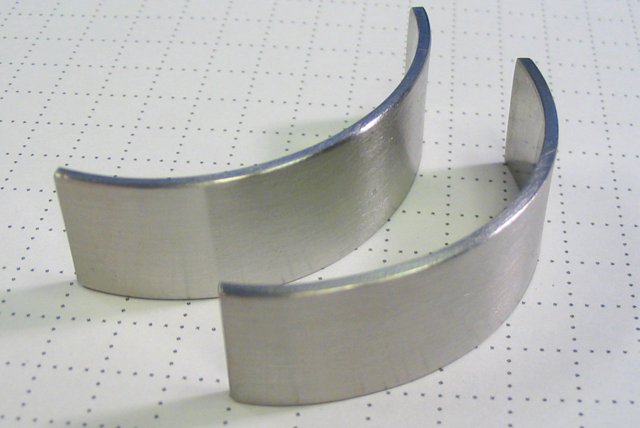

Fitting the saddle curves to match the tank's shell

(the near one still needs a bit of adjustment)

Lower supporting ribs

Ribs silver brazed into position

Two small plates will be brazed on the sides of each assembly

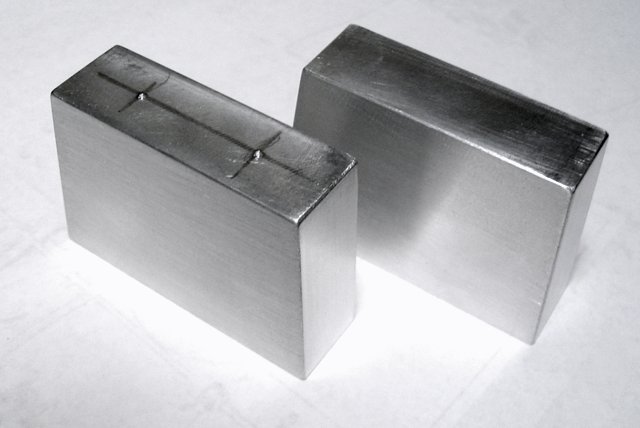

Facing mill preparing aluminum stock for the piers

Piers to be drilled and tapped (on tops and bottoms)

Completed saddles and piers bolted to a steel baseplate

Next: the fuel level indicator

This is a pressurized fuel tank, not a steam boiler. The requirement of a gauge glass in a boiler is to show only the safe range of water levels. However a fuel gauge has a somewhat different job. Like those in our cars it must indicate how much fuel is remaining in the tank. Therefore it must display the entire range from full to completely empty.

With this in mind I decided to simply use a very long gauge glass at the side of the tank with the visible portion spanning the complete distance from top to bottom. The fuel level of course will not give a linear indication of the volume of fuel since the tank is widest at the mid point and infinitely narrow at the bottom and top. It also means that the very long glass is located where it will be suseptable to being smashed easily and so will require some physical protection.

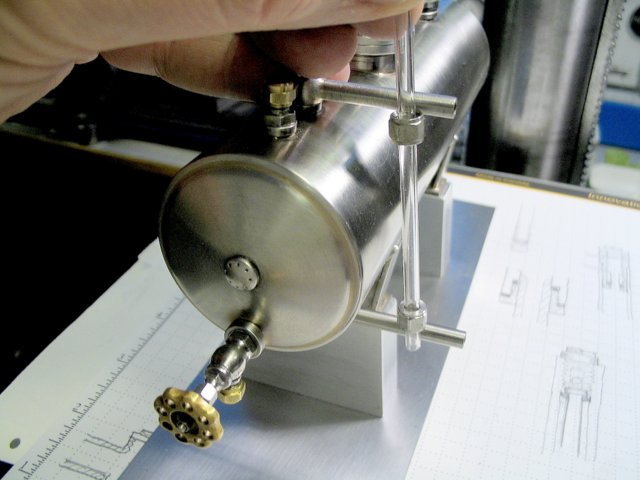

A banjo joint at the top and bottom of the shell will suit this arrangement nicely

The upper banjo connection is visible in this view

Banjo connections are reasonably easy to construct and offer a couple of advantages over many other types. Orientation is easily set (or changed) as direction does not depend on thread tightness or washer thickness. The other feature is that banjos can be installed by simply sliding in over a suitable threaded bush. My fuel gauge glass assembly can slide in from the side over the top and bottom tank openings simultaneously as a rigid one-piece unit.

Turning one of the slightly oval banjo bodies

The oval shape was to aid in mounting a pipe on the side

Reaming the drilled hole through the body

Using an odd shaped tool to create a hollow body

Creating banjo bolts from stainless steel screws

Left: original screw; Middle: head reduced; Right finished banjo bolt

The holes in the heads are for a tommy bar to tighten the bolts

(hex heads would be a suitable option)

A length of tubing silver brazed to the body completes one banjo unit

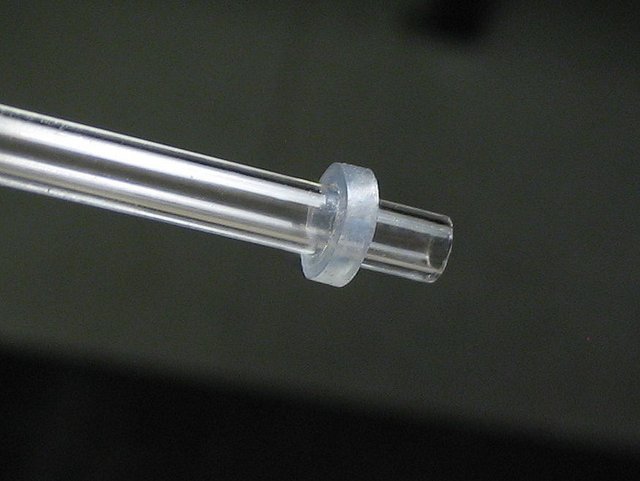

Cutting silicone washers for the gauge glass from model airplane fuel tubing

A few extras for some future project

I have used this type of gage glass packing washer for years

- they work well without any problems

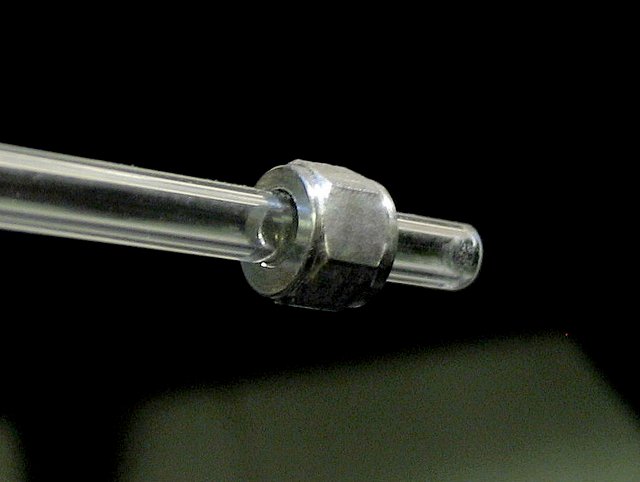

A stainless steel nut to slide over the silicone packing washer

Yet to be finished are elbows and protection rods for the glass

You are on Part 11